https://blog.durabritelights.com/wp-content/uploads/2025/02/How-To-Find-Night-Fishing-Boat-Deck-Lights-That-Wont-Blind-You.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2024/01/DuraBrite-Logo_6a362a2d-4dff-4723-a7e4-1466056fae1e_220x.png

Abstrakt Marketing2025-02-18 13:33:402025-02-18 19:36:27How To Find Night Fishing Boat Deck Lights That Won’t Blind You

https://blog.durabritelights.com/wp-content/uploads/2025/02/How-To-Find-Night-Fishing-Boat-Deck-Lights-That-Wont-Blind-You.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2024/01/DuraBrite-Logo_6a362a2d-4dff-4723-a7e4-1466056fae1e_220x.png

Abstrakt Marketing2025-02-18 13:33:402025-02-18 19:36:27How To Find Night Fishing Boat Deck Lights That Won’t Blind YouWhat You Need To Know About Marine-Grade Lighting

Even among so-called “marine-grade” lights, performance and lifespan vary vastly depending on design, engineering, and internal component quality. Before you buy lights labeled marine-grade, make sure you know everything that goes into them.

What We’ll Cover:

- What Are Marine-Grade Lights?

- Common Myths and Misconceptions About Marine-Grade Lighting

- How To Read Boat Light IP (Ingress Protection) Ratings

- Key Considerations Before You Buy Marine-Grade Lights

What Is Marine-Grade Lighting?

Marine-grade lights are specialized lighting fixtures designed to withstand harsh marine environments on boats, docks, and offshore platforms. They’re engineered to endure continuous exposure to saltwater, humidity, and extreme weather. To accomplish this, their housings and components are commonly made of corrosion-resistant materials like stainless steel, brass, and marine-grade aluminum with sturdy seals and gaskets that prevent water and moisture ingress.

More specifically, marine-grade boat lights come in a range of forms, including navigation lights, spotlights, deck lights, bait-raising lights, cabin lights, and underwater lights. As a specialized piece of lighting technology, they should not be considered a one-size-fits-all solution. We assembled this guide to help you understand the differences that set one lighting fixture apart from another.

Common Myths and Misconceptions About Marine-Grade Lights

Let’s start by setting the record straight if you’ve heard any of these common myths and misconceptions about marine-grade lighting.

Myth 1: All Marine-Grade Lights Are the Same

Some people think that all marine-grade lights offer the same level of protection and performance. If a light is labeled marine grade, it’s good enough.

Reality: Marine-grade lights vary widely in terms of quality, materials, and engineering. What sets one light apart from another often comes down to fine manufacturing and design details that can’t be deciphered through operating specs alone. Some manufacturers simply give their lights a white finish and label them “marine” without truly meeting the strict standards necessary for harsh maritime environments.

The level of corrosion resistance, durability, and water tightness ranges widely between products, so it’s critical to thoroughly research and choose a light that meets the specific standards and requirements of your marine environment. If you aren’t sure, ask or read reviews from professional captains who are on the water full-time to understand what they look for in a boat light and start narrowing down your options.

Myth 2: Metal Materials Mean Better Quality

Others may believe that the quality and performance of a marine-grade light lies solely in its material composition and that the best lights are made exclusively of metal.

Reality: Fully metal luminaires and hardware do not necessarily equate to higher-quality lights. Certain composite polymers are stronger and lighter than steel while providing better resistance to:

- Impact damage

- Stress from mismatched materials

- Saltwater corrosion

- Galvanic corrosion

- Temperature-induced stress

- Vibration-induced damage

For this reason, many recreational boats are made of the common polymer fiberglass instead of metal, and many fully metal lights are heavier and less durable than polymer options.

Myth 3: Marine-Grade Lights Are Just Normal Lights With a Special Coating

Boaters may suspect that marine-grade lights are just regular lights with a special marine coating to protect against corrosion.

Reality: Some are, but true marine-grade lights are engineered from the ground up to withstand the harsh conditions of water, salt, and UV radiation. Even powder-coating isn’t enough for a light to hold up in marine environments, as there’s a difference between marine-grade and standard powder coating, and not all paints offer UV resistance, which is critical if you don’t want your lights breaking down after a season or two.

True marine-grade lights are designed with corrosion-resistant materials, special seals, and UV-resistant lenses, not just an external coating. They also require specific procedures and prep work to ensure the surface is optimized for powder coating adhesion. Without these procedures, the coating can quickly start chipping or delaminating soon after installation.

Myth 4: Marine-Grade Lights Are Only Required for Seaworthy Vessels

New boat owners may think that marine-grade lights are only really needed for ocean-going vessels in deep-sea environments.

Reality: Saltwater is one of the harshest things a light has to endure. Corrosion is the result of exposure to water and oxygen, and the process is expedited by salt and UV radiation. Even materials that aren’t out on the sea or don’t come into direct contact with water, including stationary pier lights and metal dock roofs, corrode and degrade over time. This corrosion contributes to an increased likelihood of failure over time, making marine-grade lights essential for any application in or around the water.

Myth 5: Marine-Grade Means Waterproof

Some people assume that a marine-grade light means it’s fully waterproof.

Reality: Many marine-grade lights are designed to be water-resistant, and some are waterproof, but not all are. Before you buy, it’s pivotal to check the IP (Ingress Protection) rating of a particular light to understand the level of water resistance and compare it to what you need based on the installation location. We provide more details on how to read IP ratings below.

Myth 6: Marine-Grade Lights Are Too Expensive to be Worth the Investment

Some argue that marine-grade lights are too expensive to justify the extra cost and would rather pay the price of replacing cheaper lights when they go out.

Reality: While marine-grade lights are more expensive than standard lights, they’re generally more cost-effective over time due to their durability and resistance to harsh marine conditions. Investing in marine-grade lights can save money by reducing or eliminating the need for replacements or repairs. Having to reinstall lights costs additional time and money for the replacement parts and labor, not to mention the potential costs of accidents or injuries if your lights fail when you’re on the water.

Every boat captain’s number one priority should be safety on the water, and boat lights are the most important tool at your disposal when navigating at night or in stormy conditions. Going with cheaper lights to save on upfront costs could literally cost you your life when you need them most.

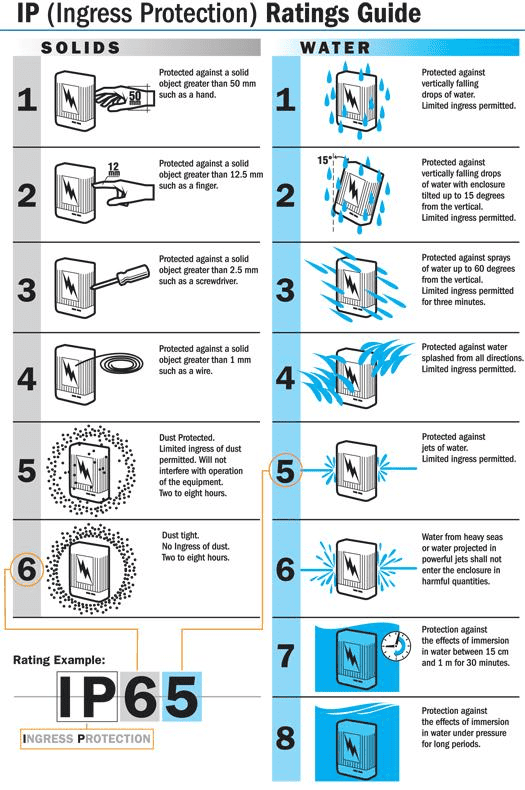

How To Read Boat Light IP Ratings

All electronics deteriorate when liquid or dust enters the device. The system of Ingress Protection (IP) ratings was devised to grade an enclosure’s resistance to the intrusion of dust or liquids. Today, it’s become one of the standard measures for durability in the electronics industry, and it’s one of the easiest ways to measure the level of water protection a particular lighting fixture offers.

If a light has an IP rating, it will always be composed of two numbers:

- The first number refers to protection against solid objects on a scale from 0 to 6, with 0 offering no protection and 6 guaranteeing no ingress of dust.

- The second number refers to the fixture’s protection against liquid on a scale from 0 to 9, with 0 offering no protection and 9 offering the highest level of protection against high-pressure hot water from different angles.

At the two extremes of the spectrum, IP 00 offers no protection against dust or liquid, while the highest rating of IP 69 is dust-tight and can withstand high-pressure hot water from any direction without harmful effects.

For boat navigation or deck lights, you shouldn’t consider any fixture rated lower than IP 65 because simply hosing them down could lead to water ingress over time. For maximum protection, we recommend only investing in lights rated IP 68 or higher if you want true marine-grade lights.

Take a look at the chart below for the full details of what IP ratings mean for marine-grade lights:

Whether you make your living on the water or you don’t want to lose your next trophy to the dark, DuraBrite offers the highest-performing marine lights available on the market today.

Key Considerations Before You Buy Marine-Grade Lights

Along with IP rating, you should also consider these factors before investing in marine-grade lights:

Thermal Stress Resistance

In saltwater environments and coastal areas, temperatures can vary widely between day and night as well as across seasons. In the Northeast United States, for example, summers are hot while winters are frigid. These extreme temperature ranges and freeze-thaw cycles are much harder on lights. Marine-grade lights should be designed with matching coefficients of thermal temperature (CTE) for different materials, so they’re capable of expanding and contracting together without cracking or weakening over time.

Corrosion and UV Resistance

Materials also need to be corrosion and UV-resistant. Corrosion is the result of oxidation, which happens when oxygen and water sit on a surface. Salt exacerbates the effects of corrosion, while UV accelerates material degradation. As a result, marine-grade lights should either feature a specialized coating or be constructed from materials inherently capable of withstanding continuous exposure to sunlight and salt.

Another force marine lights have to contend with is galvanic corrosion, which occurs when two different metals come into physical contact in the presence of an electrolyte like saltwater. It’s critical to consider in marine environments, particularly for marine-grade lights, because it can lead to rapid deterioration of materials if not properly managed.

Design engineers who understand this issue choose materials that are close together in the galvanic series to reduce the risk of corrosion. For example, using all stainless steel components together rather than mixing with aluminum can minimize galvanic corrosion. Wherever dissimilar metals come into contact, make sure to isolate them with anti-seize compounds or non-conductive nylon washers.

Seals, Waterproofing, and Pressure Relief Valves

As mentioned earlier, “marine grade” does not automatically mean waterproof. Lights rated below IP68 are more susceptible to moisture ingress over time, especially as temperature fluctuations cause seals to expand and contract, leading to corrosion or electrical failures. Marine-grade lights are often sealed in a controlled, room-temperature environment of around 77°F, but real-world conditions can vary significantly.

To counteract these stresses, marine-grade lights should incorporate a breather to equalize internal and external air pressure, preventing strain on the seals. They also prevent the light from becoming pressurized and creating a vacuum that can draw moisture into the fixture through even the smallest gaps. By combining a robust IP68 (or higher) rating with a properly designed breather system, these lights can maintain their waterproof integrity for years to come.

Maintenance Requirements

The best marine-grade lights require no more maintenance than hosing and rinsing down with boat soap after a trip on the water.

Aesthetics

While the primary priority of marine-grade lights is safety and reliability, they’re often exposed to public view at docks or marinas, so you shouldn’t compromise on performance and appearance. The best marine-grade lights balance aesthetics and reliability to enhance the overall look of your vessel without you ever doubting whether they’ll turn on when you flip the switch. You should want to show off your new boat lights rather than hide them.

Ease of Installation

The best marine-grade lights can be installed in a day or less. Marine-grade lights should be compatible with the mounting surface, whether it’s metal, fiberglass, wood, or another material. Check for compatibility with existing mounting points and ensure the mounting hardware is appropriate for the material.

Surface-mounted lights are generally easier to install because they attach directly to the surface with minimal cutting or drilling. Flush-mounted lights require more precise installation work, including cutting into the mounting surface and ensuring proper ventilation that allows heat to escape from the light.

Choose DuraBrite for True Marine-Grade Lights

With an IP 68 rating and an industry-best 10-year warranty, DuraBrite has set the new standard for marine-grade lights. That’s why they’re trusted by the likes of the NYPD Harbor Unit, the Captains of Wicked Tuna, and Lobstermen throughout Maine. Take a look at the DuraBrite Marine Collection to see which of our lights fits best for your boat, and if you need more specialized recommendations, don’t hesitate to reach out to our team for expert guidance.

Share This Post

More Like This

https://blog.durabritelights.com/wp-content/uploads/2025/02/How-To-Find-Night-Fishing-Boat-Deck-Lights-That-Wont-Blind-You.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2024/01/DuraBrite-Logo_6a362a2d-4dff-4723-a7e4-1466056fae1e_220x.png

Abstrakt Marketing2025-02-18 13:33:402025-02-18 19:36:27How To Find Night Fishing Boat Deck Lights That Won’t Blind You

https://blog.durabritelights.com/wp-content/uploads/2025/02/How-To-Find-Night-Fishing-Boat-Deck-Lights-That-Wont-Blind-You.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2024/01/DuraBrite-Logo_6a362a2d-4dff-4723-a7e4-1466056fae1e_220x.png

Abstrakt Marketing2025-02-18 13:33:402025-02-18 19:36:27How To Find Night Fishing Boat Deck Lights That Won’t Blind You https://blog.durabritelights.com/wp-content/uploads/2024/09/What-You-Need-to-Know-About-Electrostatic-Discharge-Protection-for-LEDs.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2024/01/DuraBrite-Logo_6a362a2d-4dff-4723-a7e4-1466056fae1e_220x.png

Abstrakt Marketing2024-09-20 13:37:232025-03-12 13:27:27What To Know About Electrostatic Discharge Protection for LEDs

https://blog.durabritelights.com/wp-content/uploads/2024/09/What-You-Need-to-Know-About-Electrostatic-Discharge-Protection-for-LEDs.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2024/01/DuraBrite-Logo_6a362a2d-4dff-4723-a7e4-1466056fae1e_220x.png

Abstrakt Marketing2024-09-20 13:37:232025-03-12 13:27:27What To Know About Electrostatic Discharge Protection for LEDsCreating advanced lighting solutions that excel across extreme applications, from crab-fishing in Alaska’s Bering Sea, to unforgiving power plants to mission critical law enforcement and military tactical environments, all with uncompromising quality